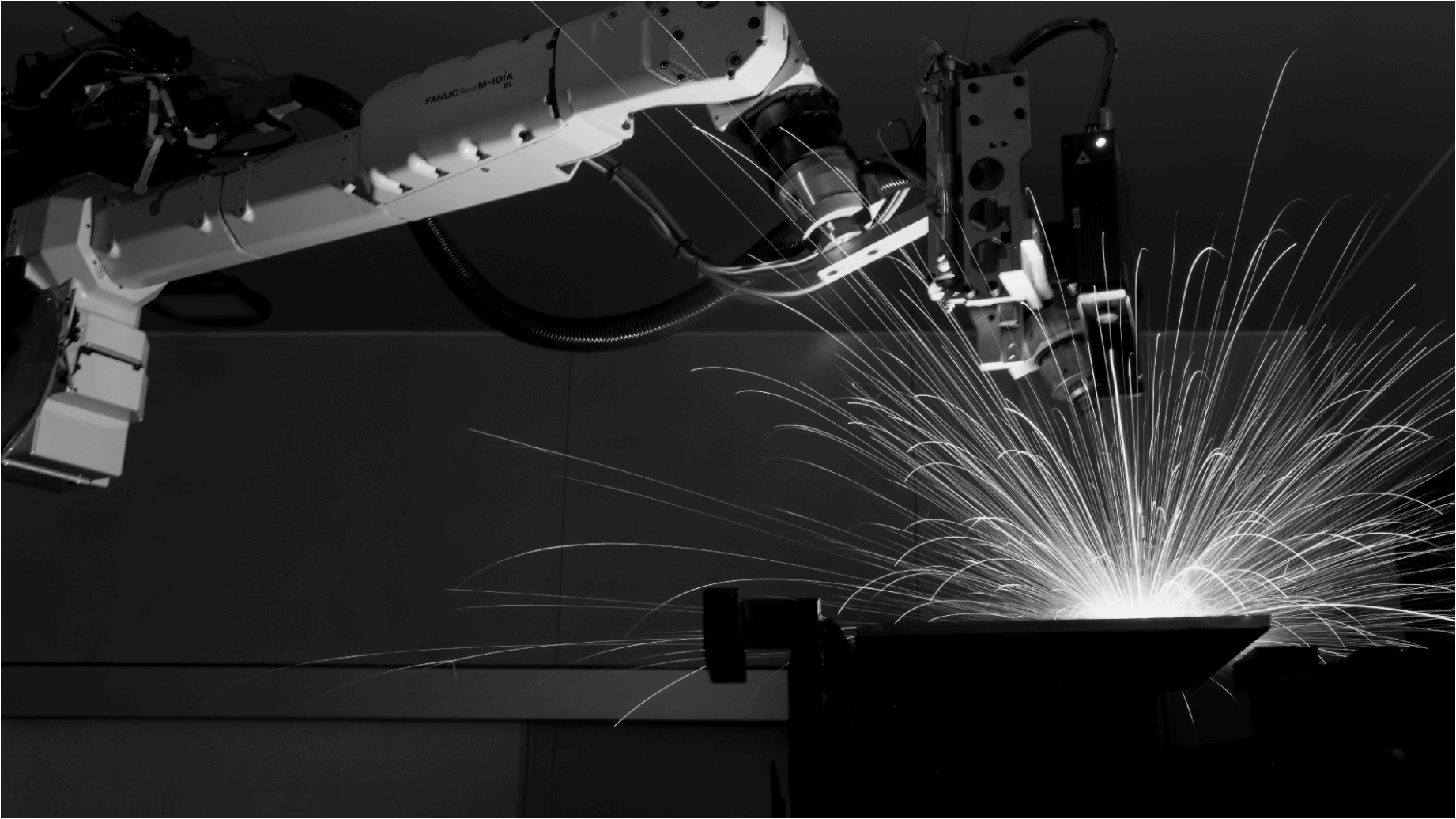

Tech Craft

Craftmanship

Go Back to the Source to Learn about the Journey of Raw Materials

Go Back to the Source to Learn about the Journey of Raw Materials

Originality penetrates into every link of the way we manufacture medical products. It seems to come from nowhere, but in there are traces for us follow. To find the beginning, we go back to the source, revisit the process by which United Imaging Healthcare(UIH) selects raw materials, and celebrate our uncompromising attitude in following a rigorous manufacturing process.

Dec 22, 2021

Dec 22, 2021