Tech Craft

Design

The Birth of Emotional Design

The Birth of Emotional Design

Dec 22, 2021

Dec 22, 2021

Tech Craft

Design

Giving Life to Products

With the rapid development of the manufacturing industry, industrial design has shouldered the sacred mission of promoting low-cost and mass production. Amidst gushing steam and deafening sounds, time flies in the high-speed operation of machines, witnessing the industrial spirit of scale, efficiency and order. A heavy visual impression, monotonous product design, and simple materials and processing have become symbols of standardized industrial products-efficient but cold.

The advent of the "post-industrial era" ushers in a new era of human-centered emotional design as industrial products become more intelligent and endowed with more humanistic care. Under the principle of usability, industrial design is facing brand-new requirements of individualization, emotion and art. Turning medical equipment from a cold tool that passively accepts instructions into an intelligent and excellent assistant for users and a meticulous and considerate caregiver for patients is the core idea throughout the entire design process of the Corporate Design Innovation Center (CDIC) of United Imaging Healthcare. Different from general industrial products, large medical equipment has longer design cycles and more rigorous development processes. Creating them is like making a mature garden from seedlings; it takes many years. The process is full of adventures and hardships. Therefore, every piece of medical imaging equipment is bound to be unique and extremely precious from the very beginning.

Design Research

Design Research

The first step for design is research, which includes data analysis, user observation, user interviews and sample collection. This process helps us discover needs, tap potential demands, and seek breakthroughs in design. Users plant a precious seed. Thanks to their participation, the seed carries humanistic and emotional genes in addition to functions and is destined to resonate with the users' deeper needs.

Brainstorming

Brainstorming

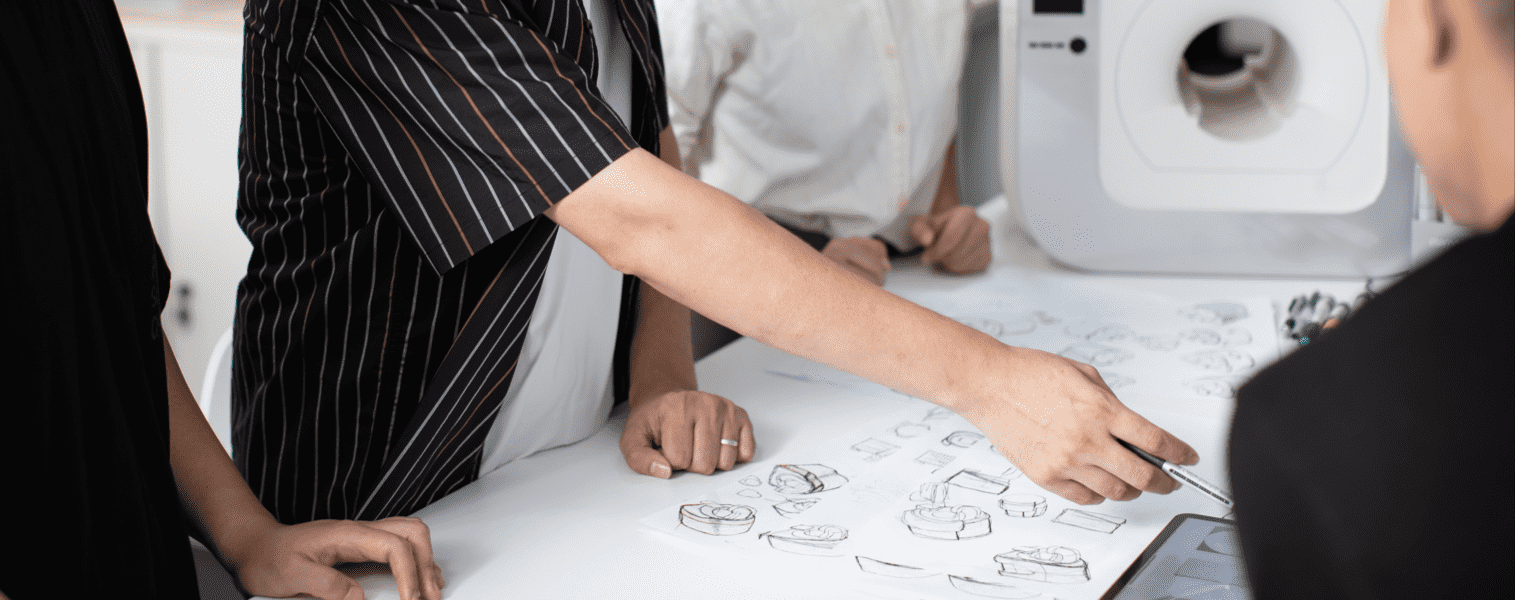

At the second stage, the seed is transferred to the care of a different team. Designers, marketers, clinical staff, and engineers form a brainstorming group to inspire each other through unlimited iterations and explore all unknown possibilities. Under a collision of interdisciplinary ideas, a large number of innovation factors emerge. After a comprehensive evaluation of usability, innovation, technological maturity, cost, humanity, emotion, etc., the best innovation factors will be incorporated into the product design sketch while other ideas are carefully reserved. After a feasibility verification with the help of a prototype, designers begin to draw product sketches. They have a comprehensive and in-depth discussion through the sketches from overall appearance to the tiniest details. After that, a large-scale review is held to pool the professional opinions of multiple parties and select a truly feasible plan for the next step.

3 Dimensional Modeling

3 Dimensional Modeling

Making three-dimensional models and renderings is an exciting step, which means all design details that directly affect product quality including key materials, parts and manufacturing processes will be finalized. In this process, many excellent innovative ideas will be ignited. After repeated, rigorous practical verifications, designers boldly introduce advanced materials and innovative techniques to optimize every part of the product from a humanistic perspective. In addition, in order to create the world's best product appearance, designers polish the model carefully, show points, lines and surfaces of the product more directly in the three-dimensional space, and render a vivid three-dimensional vision. The final selection will be affixed with the United Imaging Healthcare logo and become an official member of the United Imaging Healthcare product family.

Prototype Model

Prototype Model

The design scheme no longer stays on the computer at this stage. Designers use materials such as foam to make the initial prototype model and present the product quickly and three-dimensionally. Under the guidance of emotional design philosophy, designers and engineers work together, using the prototype model to fully test the convenience and rationality of human-computer interaction. This step is extremely crucial because it will directly influence the interaction experience between products and users. At the same time, designers and engineers work together to strike a balance between inherent use habits and interactive innovation, process and cost, appearance and structure, so as to provide products with the best performance in functional interaction, installation, utilization and visual perception for users. Thousands of discussions and attempts are all intended to eventually present the best products to users.

Structure Design

Structure Design

Excellent product design can be regarded as a complete success only with 100 percent of implementation of high fidelity. The structure design is the key step in determining whether the best design can be presented perfectly. This step requires the team to maximize their collective strength, which is a big test of their cohesion and execution. According to the three-dimensional model provided by designers, mechanical engineers design the internal mechanical structure, disassemble the model, determine the structure splitting and chip-on methods, and pay great attention to every small detail such as reinforcing ribs and screw holes. This is a wonderful stage when engineers use creativity freely. Their ingenuity in structure design not only fully implements the designers' creative ideas but even sublimates them.

System Integration

System Integration

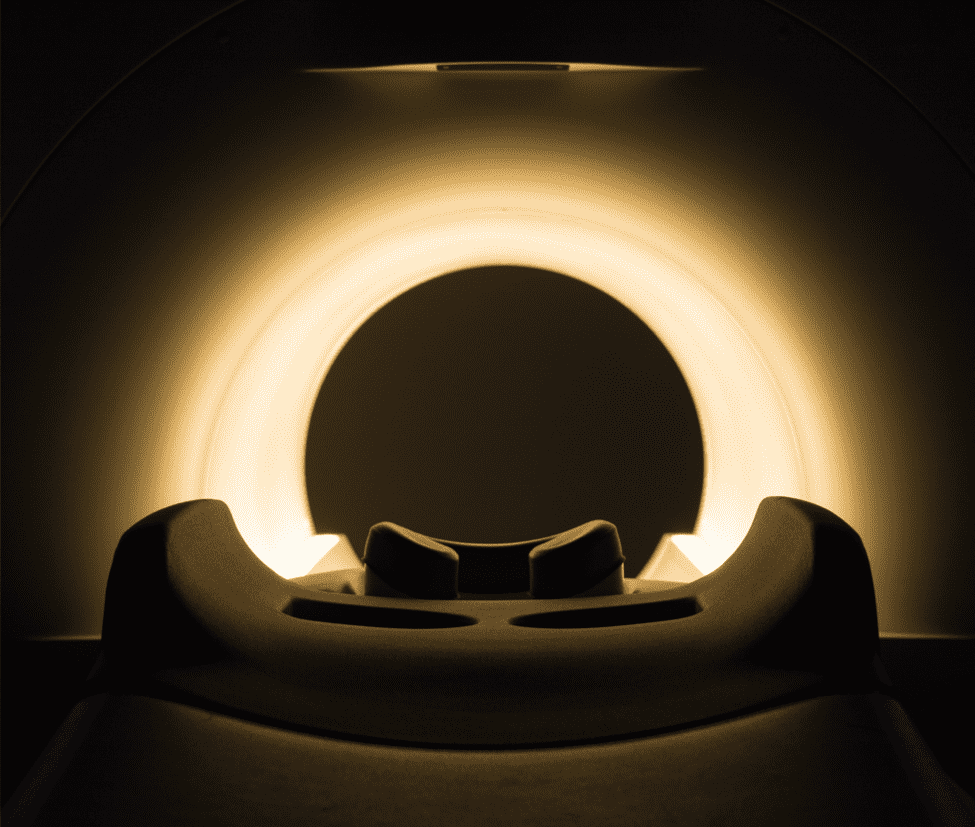

System integration is the most visible and anticipated event, which represents the sacred moment on the eve of the emergence of the product. Since it involves many subdivided professional fields, designers work with professional engineers to integrate hardware, software and case into a whole. With the operation of the machine and the interaction of sound, light and electricity, amidst the nervous anticipation and excitement of everyone, a new product life is born. The new "life" will still have to go through thousands of tests, including tests on product stability, usability and durability. Through the iterative process, it will become better in each test.

Clinical Trial

Clinical Trial

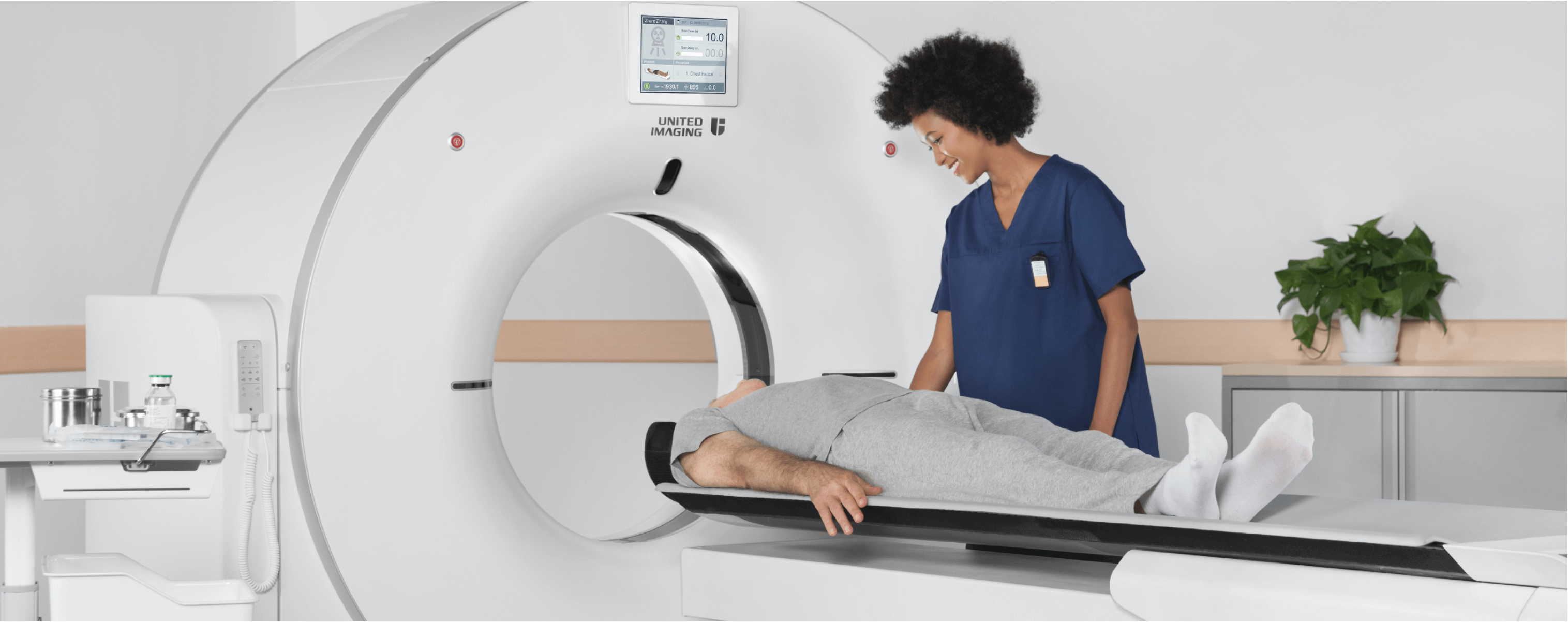

Before officially entering the market, the product needs to have the last trial in a real clinical environment, which makes us both excited and nervous because users and patients will test the comprehensive performance of the new product's safety, usability, user-friendliness and maintainability across the board. After that, the product will obtain legal status from the State Food and Drug Administration. After these tests, it finally embarks on the journey of providing care for human health. Marx once said that it is a thrilling leap from product to commodity. Only when the product reaches many users can it begin to fulfil its sacred mission, bringing benefits to the lives and work of thousands, starting a new life journey and realizing its ultimate value.